Rhinox press fittings are designed to be used as part of a press-fit system with Rhinox Multilayer Composite Pipe, eliminating the need for hot work. The stainless steel sleeve that secures the pipe to the fitting’s core is compressed by the press jaws, which are tailored for each fitting size. This process creates a joint with maximum strength and durability after pressing.

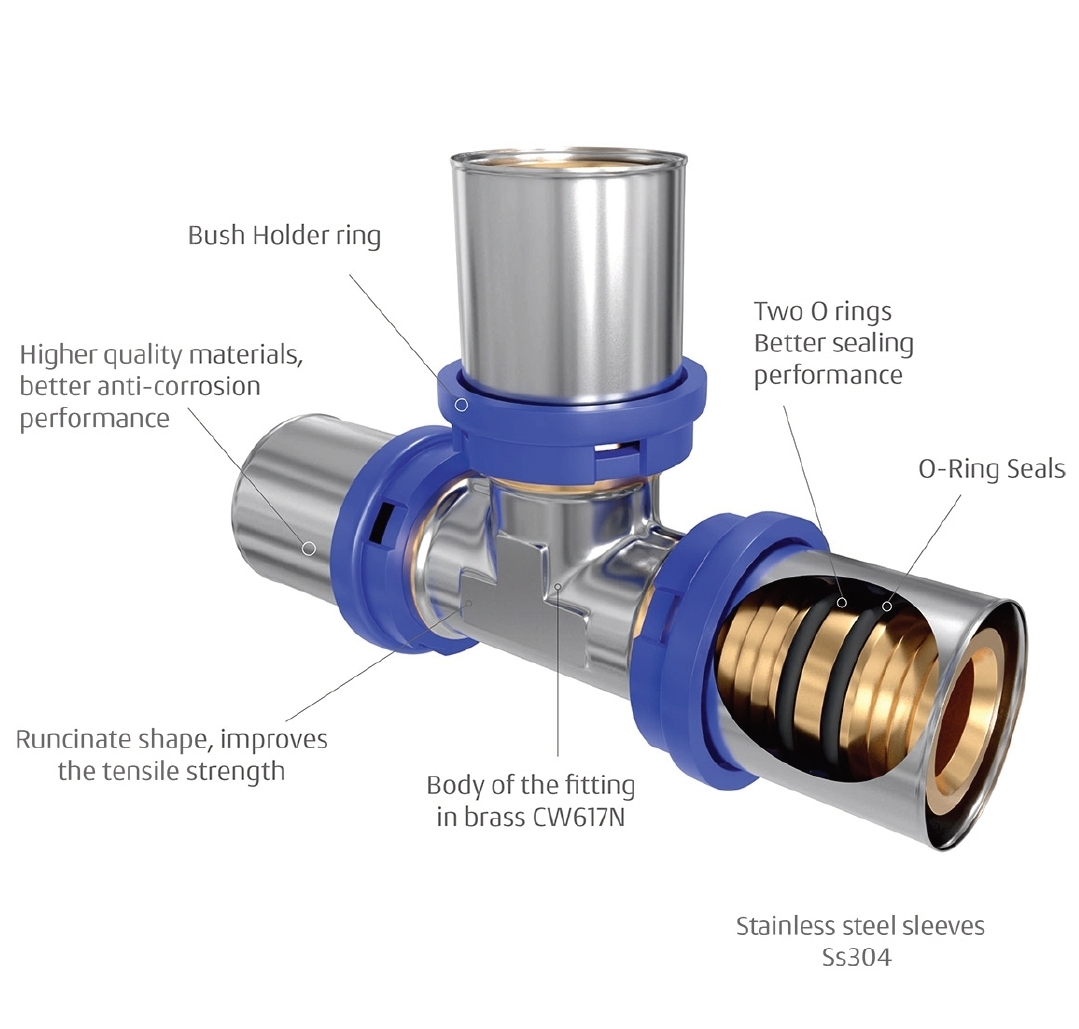

Brass Body

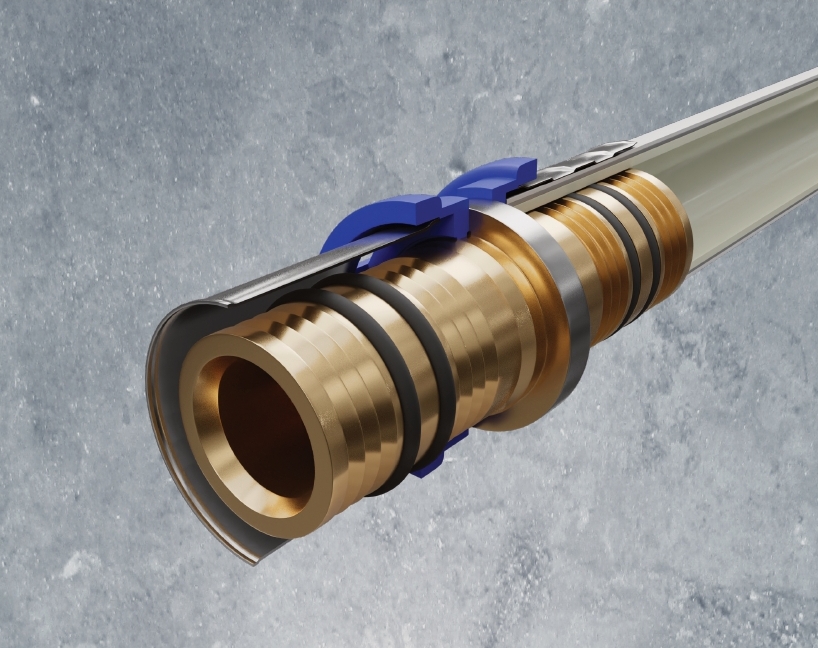

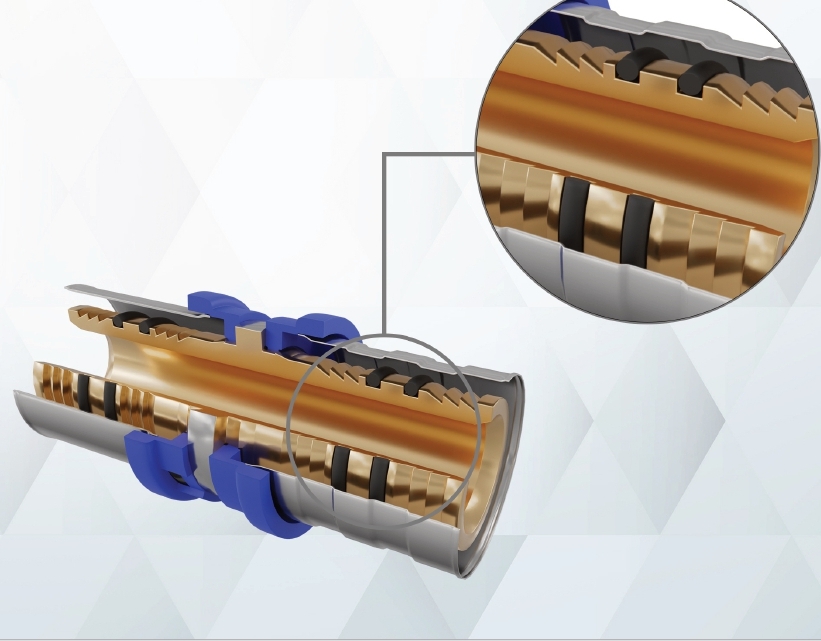

Rhinox fittings feature a nickel-plated brass body, with the plating applied only to non-fluid contact surfaces. The hose holder, designed with an anti-slip sawtooth profile, includes two O-rings for secure hydraulic sealing, ensuring long-lasting durability.

O-Ring Seals

Each fitting end is equipped with two pre-lubricated EPDM O-rings that provide waterproof sealing and accommodate material expansion, preventing leaks during testing.

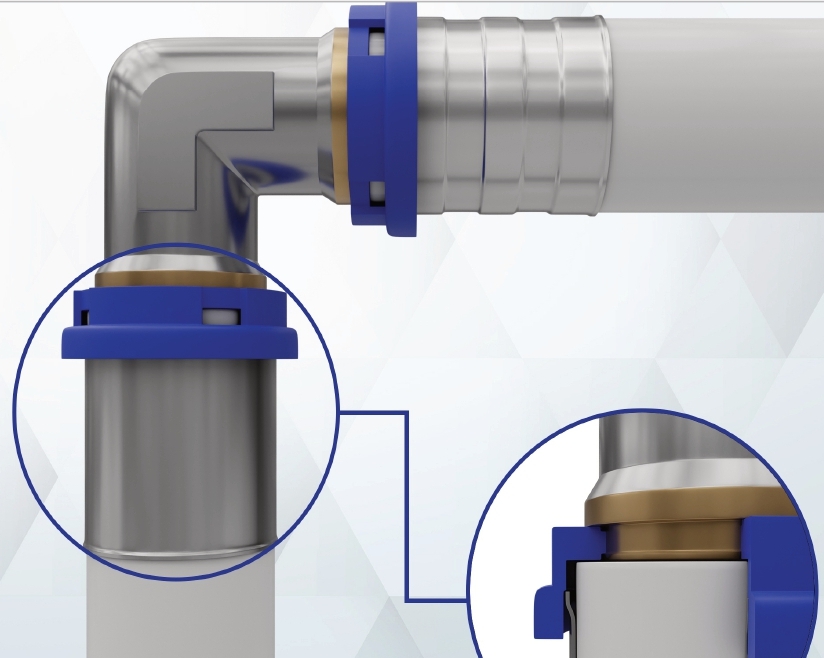

Bush Holder Ring

The blue plastic collar has sight holes, allowing installers to verify that the pipe is fully inserted into the fitting before pressing.

Stainless Steel Sleeve

Made from AISI 304 stainless steel, the sleeve is marked with pipe diameter, thickness, and pressing profile. It guarantees uniform hardness (~160 Hv) and is manufactured through a precise drawing process for consistent, reliable pressing.

**ALSO AVAILABLE IN BLUE COLOR

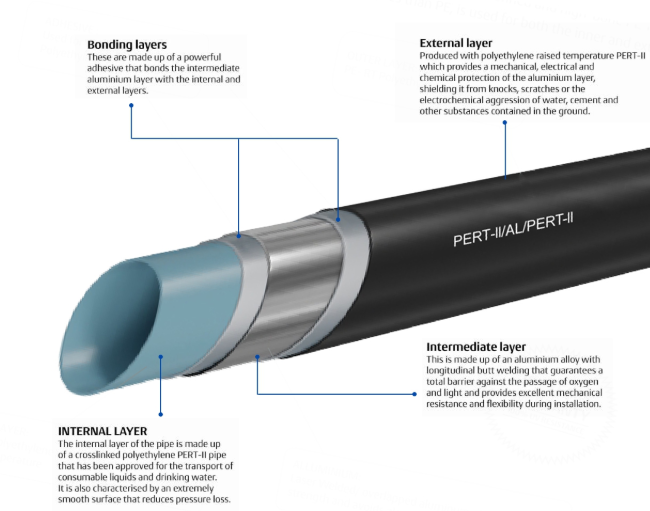

Rhinox-Wepit pipes are constructed with five layers and come in diameters ranging from 16 to 75 mm. These layers are formed almost simultaneously during production, ensuring stability and avoiding chemical reactions or temperature changes. The inner and outer layers are made from polyethylene acetate copolymer, a refined PE-RT II generation material that offers enhanced resilience to high temperatures compared to standard PE.

Rhinox-Wepit Pipes offer numerous advantages over traditional piping systems, making them an excellent choice for compressed air and other applications.

Rhinox-Wepit pipes are highly flexible and can be shaped without springing back, retaining the desired shape.

The polyethylene layer of Rhinox-Wepit Pipes provides exceptional resistance to corrosion, ensuring a longer lifespan compared to traditional metal pipes.

The unique composite construction prevents air from permeating through the pipe walls, ensuring the delivery of pure gases. The aluminum layer acts as a barrier against such permeation.

These pipes and their fittings resist a wide range of compressor oils and lubricants, making them ideal for various industrial applications.

Rhinox-Wepit Pipes have a low thermal expansion rate, similar to aluminum pipes. This reduces the need for offsets and prevents abrasion due to temperature changes.

Thanks to their flexibility, Rhinox-Wepit Pipes require fewer fittings, such as elbows and couplers, optimizing flow rates and reducing potential leakage points.

Even when bent within the recommended radius, Rhinox-Wepit Pipes maintain their strength without any loss in performance.

Up to 90% lighter than other piping systems like GI, Aluminum, and PPR pipes, Rhinox-Wepit Pipes are easy to handle while withstanding high pressures of up to 232 psi.

The smooth inner layer of Rhinox-Wepit Pipes ensures superior flow rates, with a high Hazen-Williams flow coefficient of C=150, maintaining consistent flow over time.

Rhinox-Wepit Pipes are an excellent choice for delivering gaseous carbon dioxide in food and beverage applications, made from food-grade polyethylene.